Cellophane Wrapping Machine For Pharmaceutical Blister Packs

| Specification | |

| Model | CSC-350 |

| Packaging Material | Bopp film and gole tear tape |

| Packing Speed | 30-60 packs / min |

| Packing Size | (L) 300 x (W) 120 x (H) 60 mm |

| Electric Supply & Power | 220V 50Hz 5kw |

| Overall dimensions | (L)2000×(W)800×(H)1400mm |

| Weight | 600kg |

| Electric Configuration | |

| Name | Brand |

| Breaker | Schneider / France |

| Emergency Stop Button | Schneider / France |

| Button | Schneider / France |

| Knob | Schneider / France |

| Intermediate Relay | Omron / Japan |

| Solid-state Relay | Omron / Japan |

| Temperature Controller | Aiset /China |

| Counter | Aiset /China |

| Transducer | Delta / Taiwan |

| Proximity Switch | Toky / China |

| Switching Power Supply | MeanWell / Taiwan |

| Motor | CPG / Taiwan |

Machine Introduction:

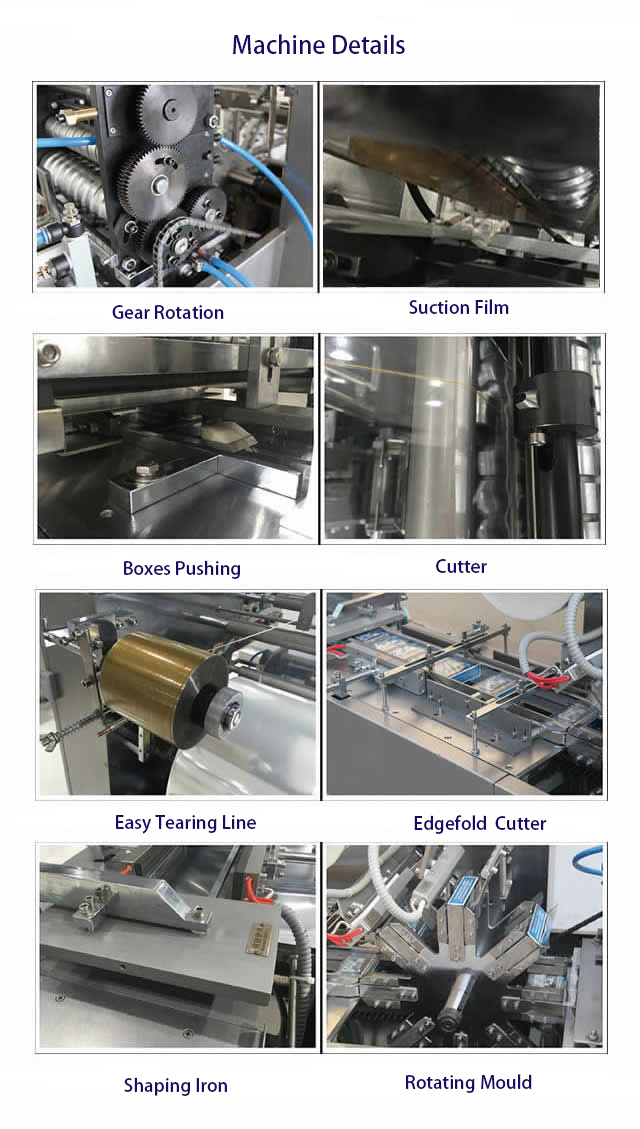

Cellophane wrapping machines are automated devices that can wrap products quickly and efficiently, ensuring a secure and attractive packaging. These machines typically consist of the following components:

Feeding System: The feeding system is responsible for delivering the products to the wrapping machine. It can be a conveyor belt or a mechanical system that moves the items into the packaging area.

Film Roll Holder: The machine has a holder or spindle to hold the roll of cellophane film. The film is unwound from the roll and fed into the wrapping area.

Wrapping Station: This is the core part of the machine where the actual wrapping takes place. The product is placed on the wrapping platform, and the cellophane film is pulled over it. The film is then sealed using heat or adhesive, creating a tight and secure wrap around the product.

Cutting Mechanism: After the sealing process, a cutting mechanism cuts the cellophane film, separating it from the rest of the roll. This ensures that each wrapped product has a neat and finished appearance.

Control System: The machine is equipped with a control panel or computer interface that allows operators to set parameters such as film tension, sealing temperature, cutting length, and wrapping speed. This helps to customize the wrapping process based on the specific requirements of the product.

Samples:

FAQ for Cellophane wrapping machine:

Q1: What is a cellophane wrapping machine?

A cellophane wrapping machine is a packaging machine designed to wrap products in cellophane film. It automates the process of securely and attractively packaging items, such as food products, confectionery, cosmetics, and pharmaceuticals.

Q2: What are the advantages of using a cellophane wrapping machine?

Enhanced product protection: Cellophane wrapping provides a transparent barrier that protects products from moisture, dust, and other contaminants.

Improved shelf appeal: Cellophane offers a visually appealing packaging solution, allowing consumers to see the product while still maintaining a protective layer.

Tamper-evident packaging: Cellophane wrapping can provide a tamper-evident seal, ensuring the integrity of the product.

Efficiency and speed: Cellophane wrapping machines automate the packaging process, increasing productivity and reducing labor costs.

Q3: What types of products can be wrapped using a cellophane wrapping machine?

Cellophane wrapping machines are versatile and can be used to wrap various products, including:

Food items: Chocolates, cookies, biscuits, snacks, etc.

Confectionery: Candy, lollipops, chewing gum, etc.

Cosmetics: Perfume boxes, soap bars, cosmetic sets, etc.

Pharmaceuticals: Medicine boxes, blister packs, etc.

Miscellaneous items: Gift boxes, small electronic devices, promotional items, etc.

Q4: Are cellophane wrapping machines easy to operate?

Cellophane wrapping machines are designed for user-friendly operation. They typically feature intuitive controls and settings that can be adjusted to accommodate different product sizes and packaging requirements. However, some level of training and familiarization with the specific machine may be required for optimal operation.

Q5: Can cellophane wrapping machines accommodate different product sizes?

Yes, cellophane wrapping machines are often adjustable to accommodate a range of product sizes. They typically offer options to customize the wrapping dimensions, film tension, and cutting length to suit the specific requirements of the products being wrapped.

Q6: Are cellophane wrapping machines compatible with other types of packaging materials?

Cellophane wrapping machines are specifically designed for cellophane film. However, some machines may have the capability to work with other types of films, such as BOPP (Biaxially Oriented Polypropylene) or PVC (Polyvinyl Chloride). It's important to consult the machine manufacturer or supplier to understand the compatibility and options available.

Q7: What is the production capacity of a cellophane wrapping machine?

The production capacity of cellophane wrapping machines can vary depending on the specific model and configuration. It can range from a few dozen to several hundred products wrapped per minute. The exact speed and capacity should be provided by the manufacturer or supplier based on the specific machine model.

Q8: Are cellophane wrapping machines suitable for small-scale businesses?

Yes, cellophane wrapping machines are available in a range of sizes and capacities, making them suitable for both small-scale and large-scale businesses. There are compact and cost-effective models available that cater to the needs of smaller operations.