Automatic Aroma Diffuser Stick Cartoning Machine

Technical Parameter:

| Model | CSZ-450 |

| Packing speed | 40-50cartons/min |

| Size of package | L(100-450)mm×W(30-70)mm×H(30-70)mm |

| Cardboard material | 250-450g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150) x (90-170)mm |

| Instruction size (Fold) | (1-4) Fold |

| Motor power | 1.5kw |

| Power supply | 380V 50HZ |

| Minimum Air pressure | 0.5-0.8 Mpa |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

| Overall dimension | L3400mm×W1174mm×H1800mm |

| Weight | 1500Kg |

Electric Configuration:

PLC

CPIE-N30DT-D/Omron

PLC Extened

Module

CPIE-C1F11/Omron

Touch Screen

NB7W-TW00B/Omron

Sensor

E3Z-D61/Sick

Frequency

3G3JZ-A4015/Omron

Relay

MY2 NJ24V/Omron

Button

XB2/Schneider

Emergency Stop

ZB2 BC4D/Schneider

Electromagnetic

Valve

4V210-08/Airtac

Pressure

Regulator Valve

BFR-2000/Airtac

Proximity

Switch

TL-Q5MC1/Omron

AC contactor

LC1E3210M5N/Schneider

Air switch

3P32A 1P6A/Schneider

Vaccum Sounder

ABM20-C/SMC

Machine introduction:

The PLC-controlled cartoning machine utilizes a photoelectric switch to monitor the conveyor belt and ensure proper feeding of materials such as sticks, fresh-keeping film, and aluminum foil rolls. When the material feed is empty, it will automatically cancel the packaging process to prevent wastage. The machine also features automatic waiting functions to match the production capacity of other equipment in the production line. It can be seamlessly connected with multiple rewinders to enhance production efficiency.

Machine Features:

1.The cartoner is equipped with top-quality electrical components from renowned international brands such as Omron.

2.It automatically detects the number of items and checks that the cartons and items are in place before initiating the packaging process. The machine will not start packaging if there is no material to feed, minimizing waste.

3.The machine displays fault alerts, packaging speed, and the number of finished items automatically.

4.The mechanical feeding system is stable and stops at the expected position, ensuring accurate and consistent packaging.

5.The machine can be fitted with a material bucket to synchronize with the conveyor belt and improve the speed of packaging and overall automation, reducing labor costs.

6.The shell of the machine is made of high-quality stainless steel and aluminum, while the electrical components are sourced from trusted German brands, ensuring long-lasting durability.

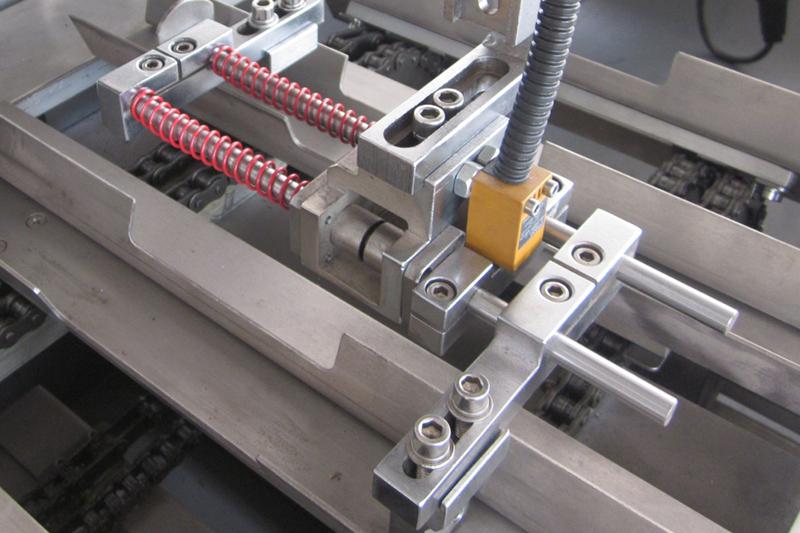

Detailed Pictures: