Preservative Film Rolls Box Packaging Machine

Technical Parameter:

| Model | CSZ-450 |

| Packing speed | 40-50cartons/min |

| Size of package | L(100-450)mm×W(30-70)mm×H(30-70)mm |

| Cardboard material | 250-450g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150) x (90-170)mm |

| Instruction size (Fold) | (1-4) Fold |

| Motor power | 1.5kw |

| Power supply | 380V 50HZ |

| Minimum Air pressure | 0.5-0.8 Mpa |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

| Overall dimension | L3400mm×W1174mm×H1800mm |

| Weight | 1500Kg |

Electric Configuration:

| PLC | CPIE-N30DT-D/Omron |

| PLC Extened Module | CPIE-C1F11/Omron |

| Touch Screen | NB7W-TW00B/Omron |

| Sensor | E3Z-D61/Sick |

| Frequency | 3G3JZ-A4015/Omron |

| Relay | MY2 NJ24V/Omron |

| Button | XB2/Schneider |

| Emergency Stop | ZB2 BC4D/Schneider |

| Electromagnetic Valve | 4V210-08/Airtac |

| Pressure Regulator Valve | BFR-2000/Airtac |

| Proximity Switch | TL-Q5MC1/Omron |

| AC contactor | LC1E3210M5N/Schneider |

| Air switch | 3P32A 1P6A/Schneider |

| Vaccum Sounder | ABM20-C/SMC |

Machine Introduction:

The machine designed to apply to pack preservative film, aluminum foil rolls, and some other long cylinder objects. The applicable packages range is 100-450mm in length, 20-80mm in width and 20-90mm in height while special sizes can be customized.

Machine Features:

1.The high-speed cartoner is equipped with various devices, including a sensor, photoelectric, and mechanical overload protection system, to form a complete monitoring, alarm, and fault display system.

2.The machine features an intelligent control system, which can detect when there are no items loaded and stop conveying cartons, as well as stop spraying glue when there is no carton available.

3.It will sound an alarm if the carton does not reach the correct position and shut down the machine when it is overloaded, further enhancing safety.

4.The entire machine is controlled by a user-friendly PLC man-machine interface, allowing for easy operation and monitoring.

5.It also utilizes a photoelectric switch to monitor the feeding of materials on the conveyor belt, preventing packaging waste by automatically canceling carton suction and glue spraying when the material feed is empty.

6.The machine also has an automatic waiting function, which can adjust to the production capacity of other equipment, such as rewinders, to optimize the entire production line's efficiency.

7.Multiple rewinders can be connected to this equipment to form a complete production line.

8.The size of the carton determines the length of the packaging machine, making it versatile and adaptable to different packaging needs. Overall, the high-speed cartoner is a highly efficient, safe, and flexible packaging solution suitable for various industries.

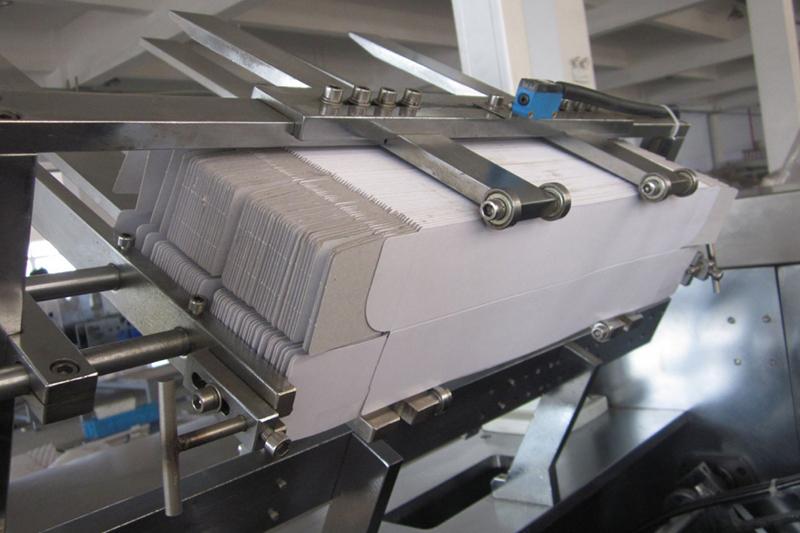

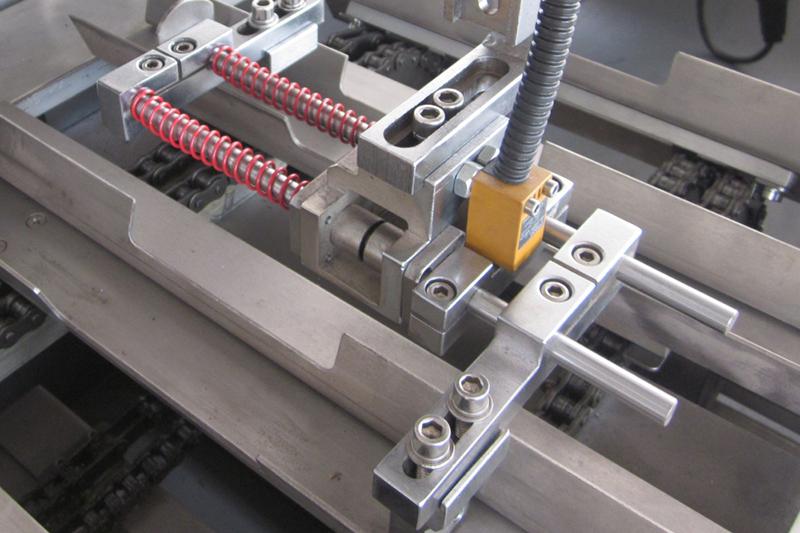

Detailed Pictures: