Milk Powder Automatic Cartoning Machine

Technical Parameter:

| Model | CSZ-180 |

| Packing speed | 30-80cartons/min |

| Size of package | L(70-280)mm×W(80-180)mm×H(30-90)mm |

| Cardboard material | 250-450g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150) x (90-170)mm |

| Instruction size (Fold) | (1-4) Fold |

| Motor power | 1.5kw |

| Power supply | 380V 50HZ or 220V 50HZ |

| Minimum Air pressure | 0.5-0.8 Mpa |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

| Overall dimension | L4000mm×W1280mm×H1900mm |

| Weight | 1400Kg |

| PLC | CPIE-N30DT-D/Omron |

| PLC Extened Module | CPIE-C1F11/Omron |

| Touch Screen | NB7W-TW00B/Omron |

| Sensor | E3Z-D61/Sick |

| Frequency | 3G3JZ-A4015/Omron |

| Relay | MY2 NJ24V/Omron |

| Button | XB2/Schneider |

| Emergency Stop | ZB2 BC4D/Schneider |

| Electromagnetic Valve | 4V210-08/Airtac |

| Pressure Regulator Valve | BFR-2000/Airtac |

| Proximity Switch | TL-Q5MC1/Omron |

| AC contactor | LC1E3210M5N/Schneider |

| Air switch | 3P32A 1P6A/Schneider |

| Vaccum Sounder | ABM20-C/SMC |

Machine Introduction:

This packaging machine is designed with a compact size of 4000mm x 1280mm x 1900mm and a lightweight body of 1400kg. It is capable of accommodating packages of various sizes, ranging from 70-280mm in length, 80-180mm in width, and 30-90mm in height. Customization options are also available for unique packaging requirements.

With a top speed of 80 cartons per minute, this machine operates efficiently to handle high-volume packaging needs. On average, it can process 40-70 cartons per minute.

Machine Features:

1.Versatile Usage: This cartoning machine can be used independently or in a production line, along with other devices like a blister pack cartoning machine, hot melt glue cartoner, etc. It has a wide application range and multiple usages.

2.Efficient and User-friendly: The machine is designed to be efficient, running under PLC control. Its simple structure makes it easy to maintain.

3.Automatic Packaging: The cartoning machine automatically retrieves packages from the carton storage area, opens cartons, packages products, prints batch numbers, seals cartons, and eliminates waste through a transmission series that requires no manual labor.

4.High Accuracy: The entire machine is equipped with a German SICK infrared protector to track and detect each step, ensuring the normal operation of the process. Various types of sealing can be chosen, and there is no need to change molds for packaging cartons of different sizes. The machine can be adjusted according to the package size.

5.Robust and Durable: The frame and board of the cartoning machine are strong and durable, with both the main drive motor and clutch installed in the machine. The drive systems are installed on the baseplate of the machine, and the torque overload protector protects the main drive motor and other parts against corrosion and performance issues.

6.The packaging process is designed to be efficient and reliable. When there is no carton available, the machine will automatically stop the packaging process. Similarly, when there is no item available, the packaging process will pause until items are available again.

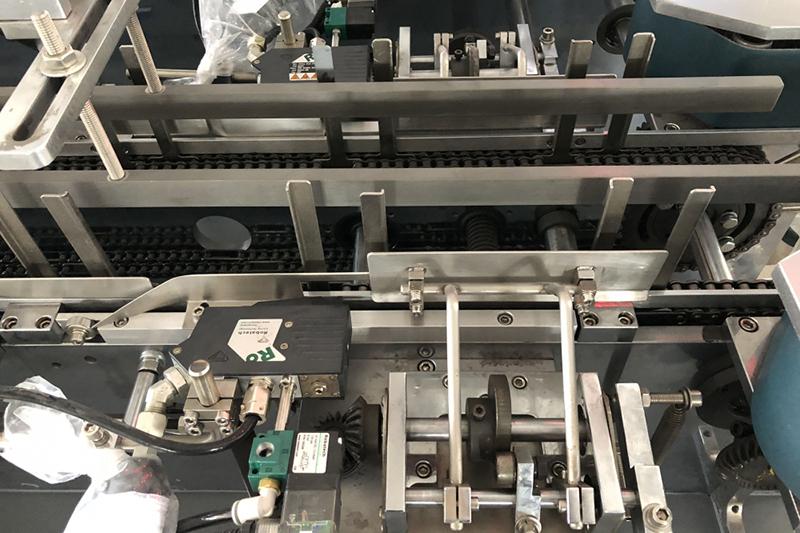

Detailed Pictures: